preztoy,

I am always happy to help out anyway I can however, I don't have any patterns for those. I made them 7 years ago for starters and I made my own patterns for a onetime use only.I can tell you HOW I made them however.

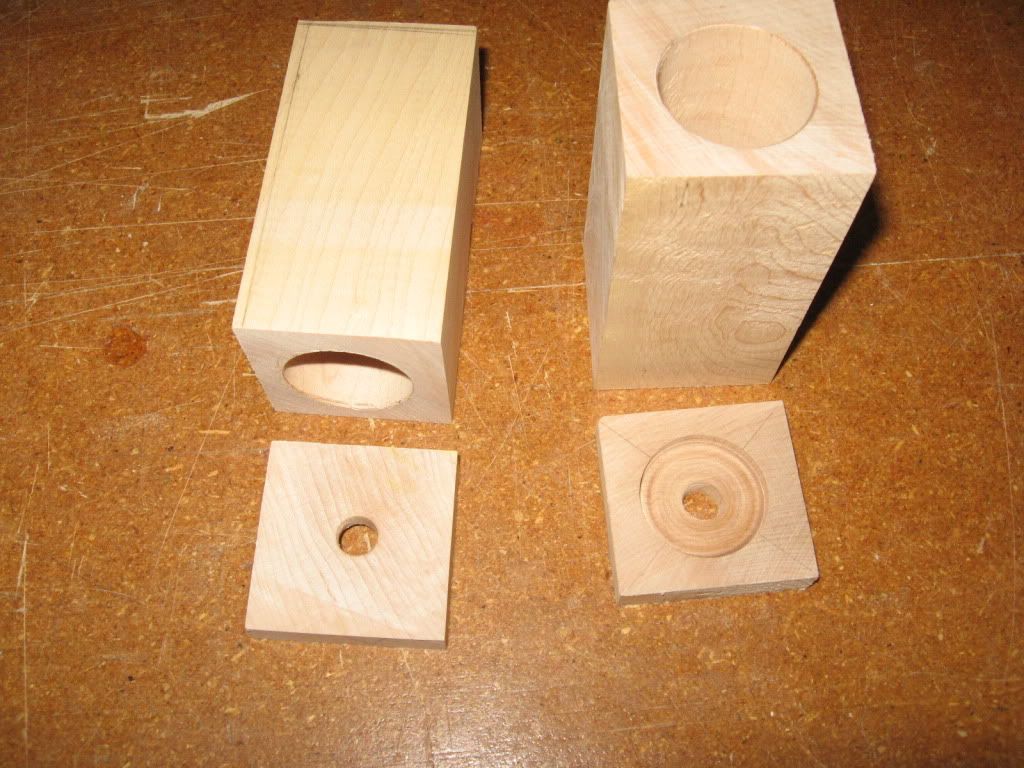

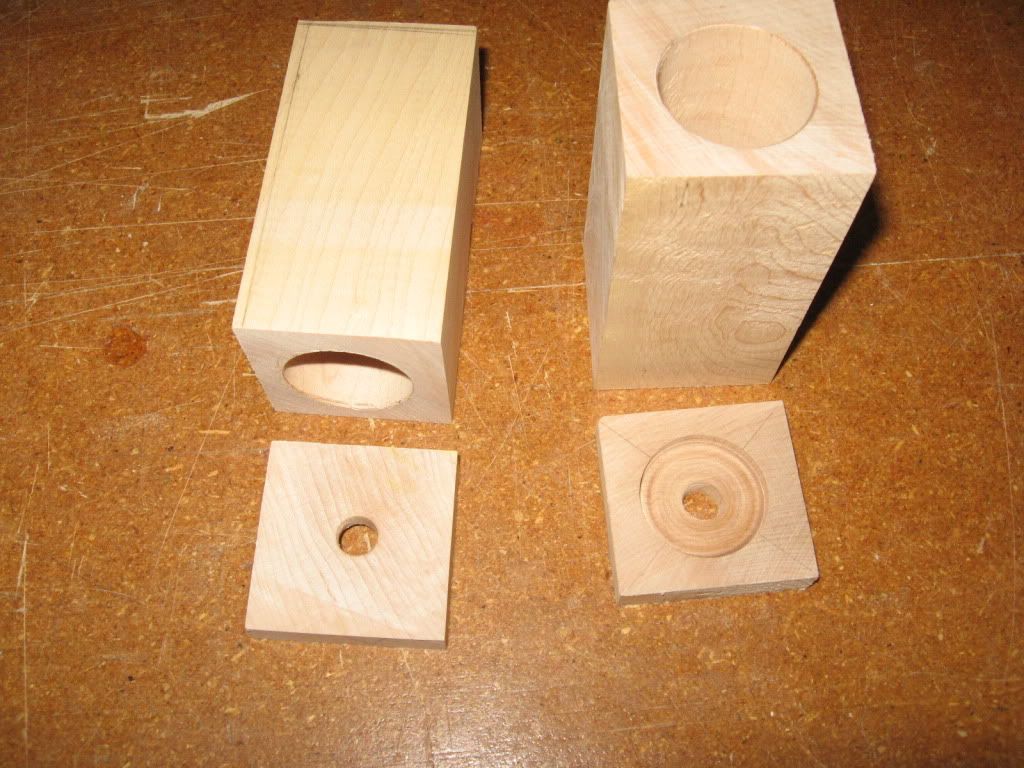

I started by using some 1-1/2" square blanks about 4" tall. Using a table saw I sliced off about 3/8" off of each end. Then I drilled a 1" hole down the center of the largest piece and a 3/8" hole in the bottom piece. I re-glued the top and bottom pieces back on the center (larger) piece so that it looked like the original blank but, was hollow.

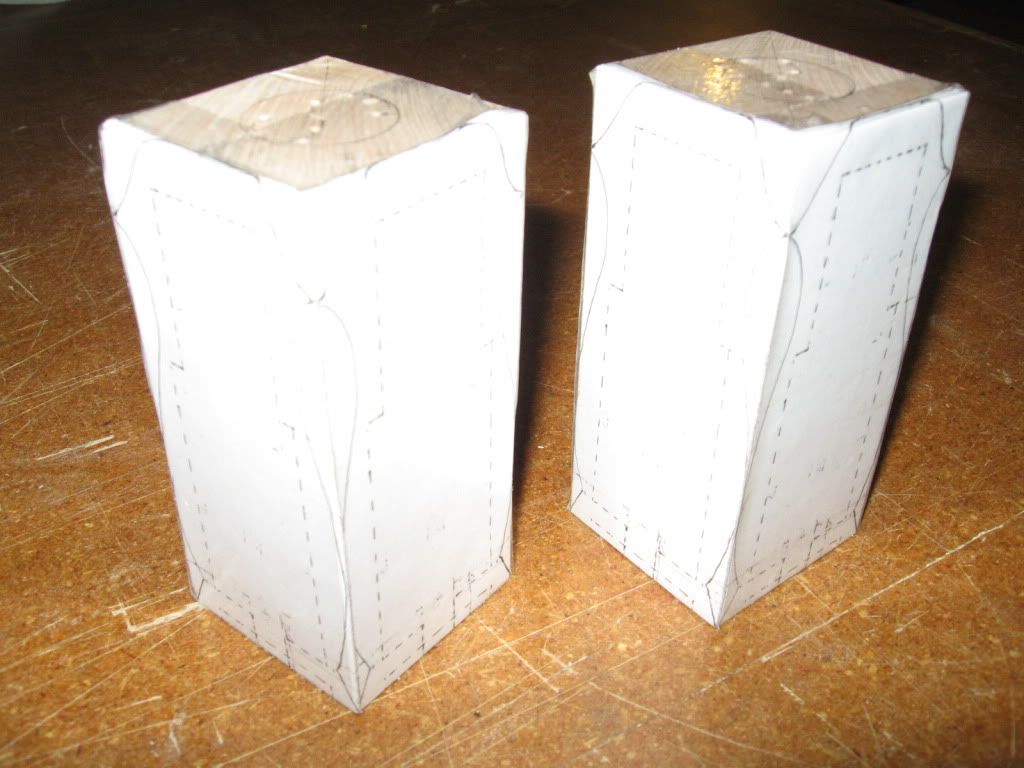

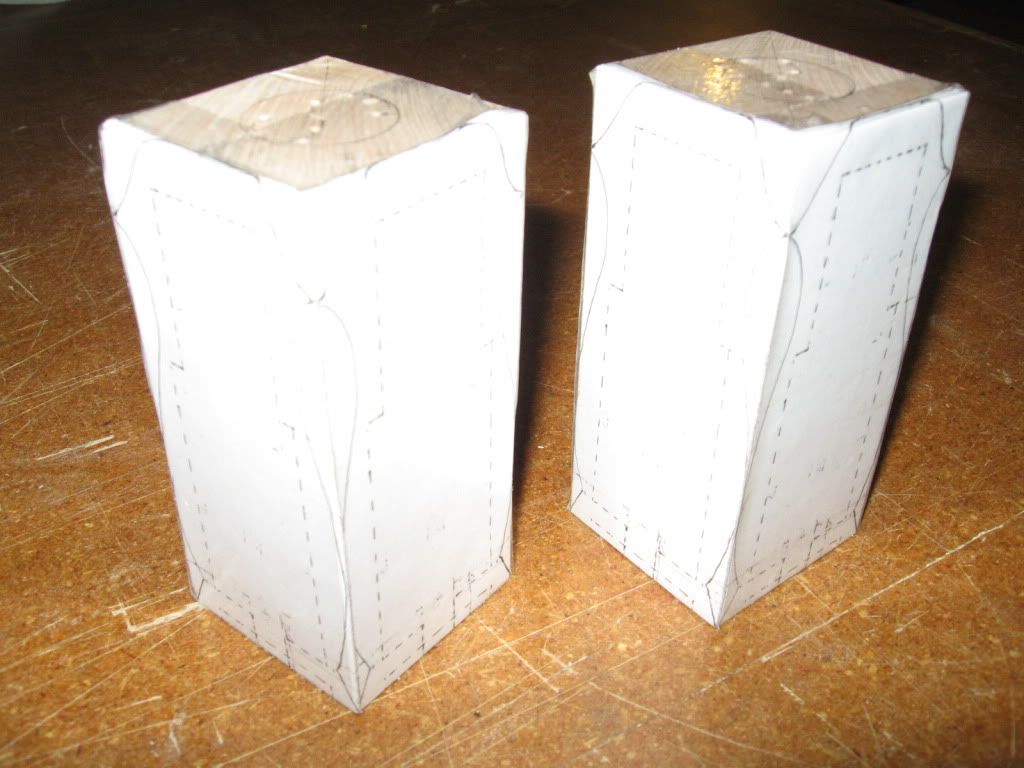

I drew my own patterns on paper carefully using the measurements of the blank and keeping in mind that there was a 1" hole in there

I made the pattern to cover two sides of the blank after being folded in half to form an L shape. Then cut them out as you do with a 3D piece.

You can tape the "drop" pieces back in to keep everything square for cutting the in the other direction.

Then drill small holes in the center of the top piece (so the salt can come out

) Sand, finish and add a cork for the bottom filler hole.

Nothing to it.....Plan on making a bunch of them. As I said the possibilities are endless and EVERY ONE OF THEM is a bit different making them truly "One Offs".

Hope that helps you a bit.

Rog

I made the pattern to cover two sides of the blank after being folded in half to form an L shape. Then cut them out as you do with a 3D piece.

I made the pattern to cover two sides of the blank after being folded in half to form an L shape. Then cut them out as you do with a 3D piece.