106

Pattern Requests. / Re: Fonts that can be used for scrolling

« on: December 07, 2015, 09:43:12 am »

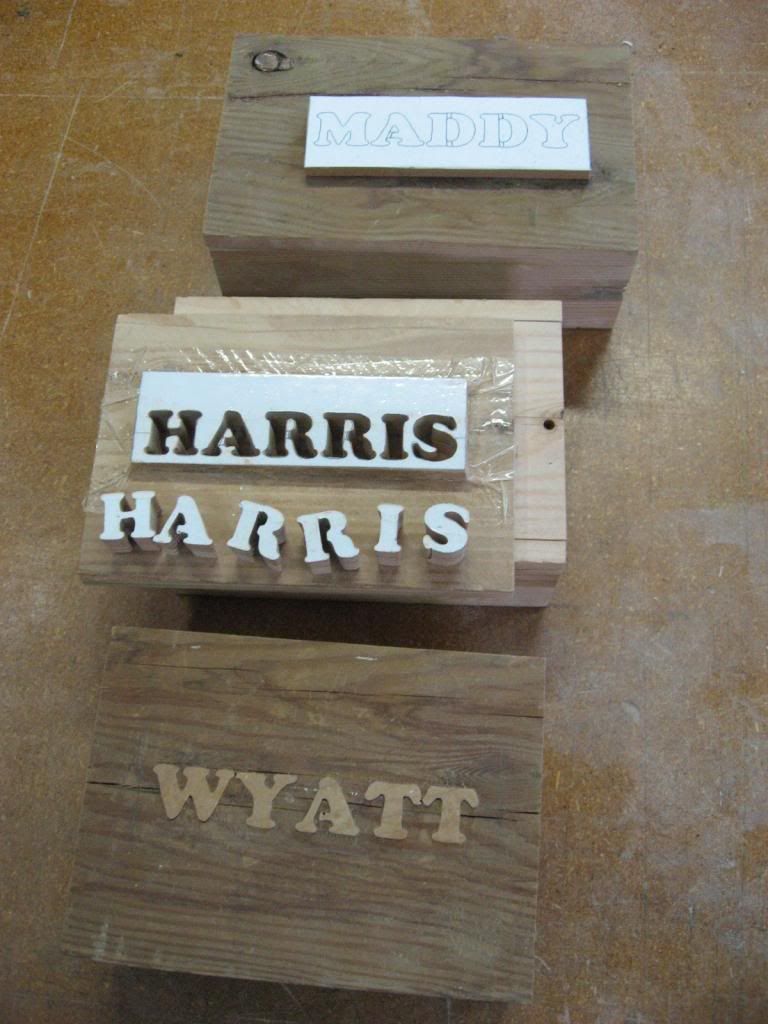

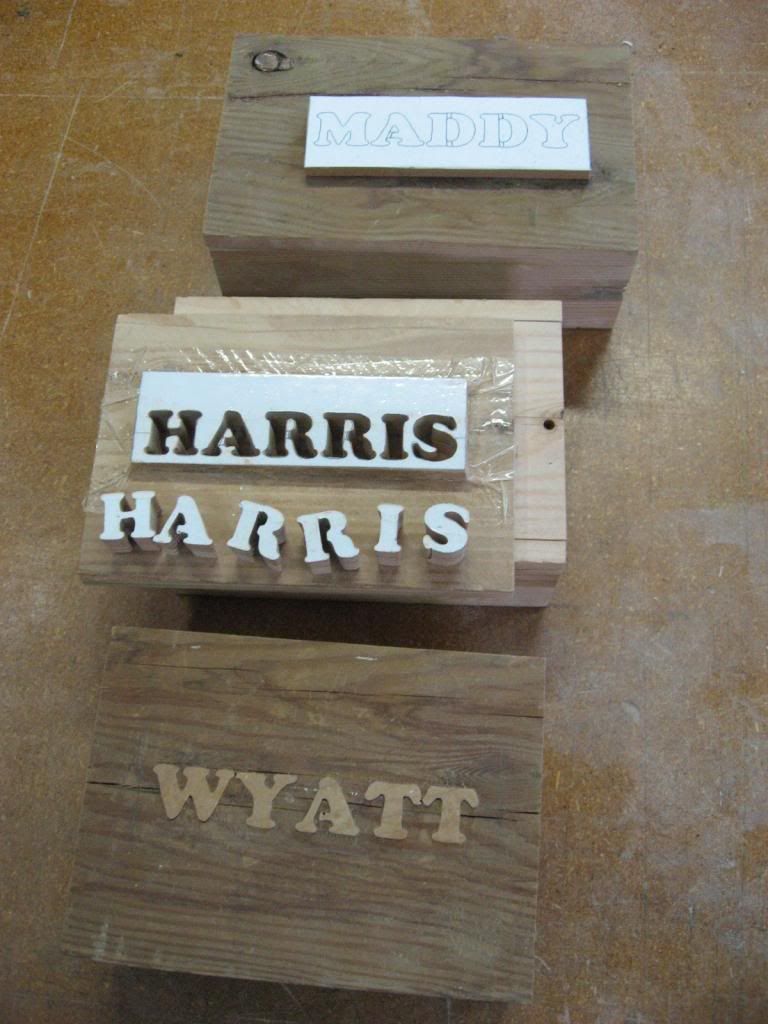

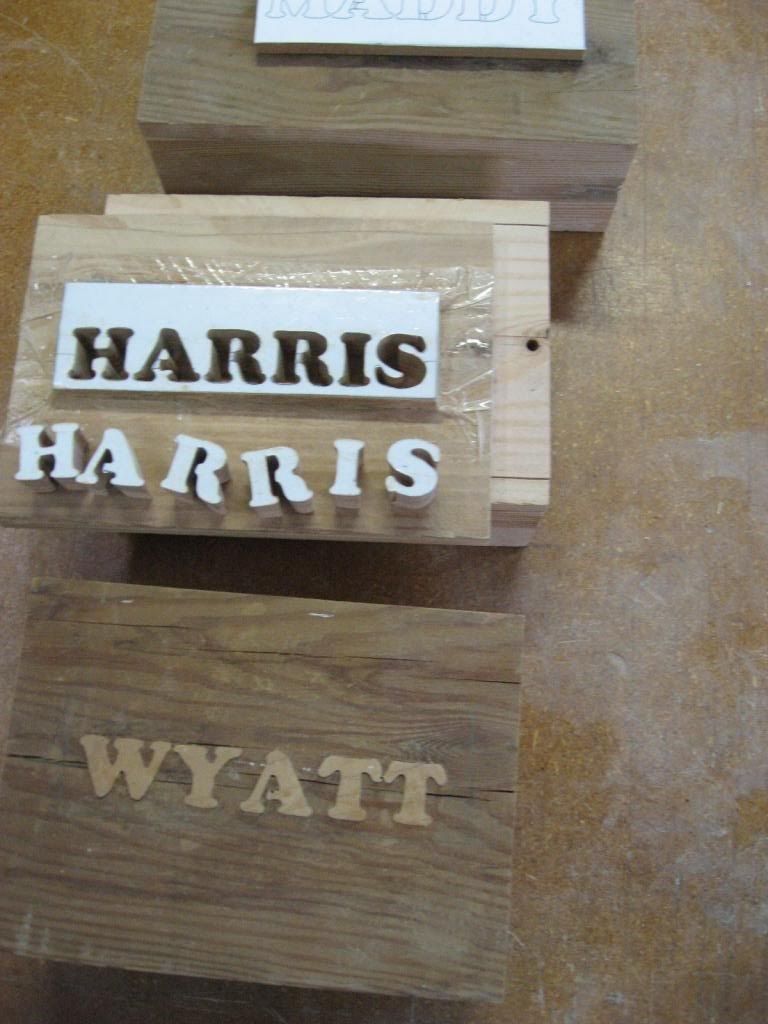

You can scroll saw almost any font that appeals to you!

Print out the words in the font you like and use a pencil, pen or sharpie to mark in bridges to keep letters with centers in place. That works on script also. Once finished the bridges are hardly noticeable on the project.

If you have a bit of drawing talent, you can design your own font. The possibilities are endless!

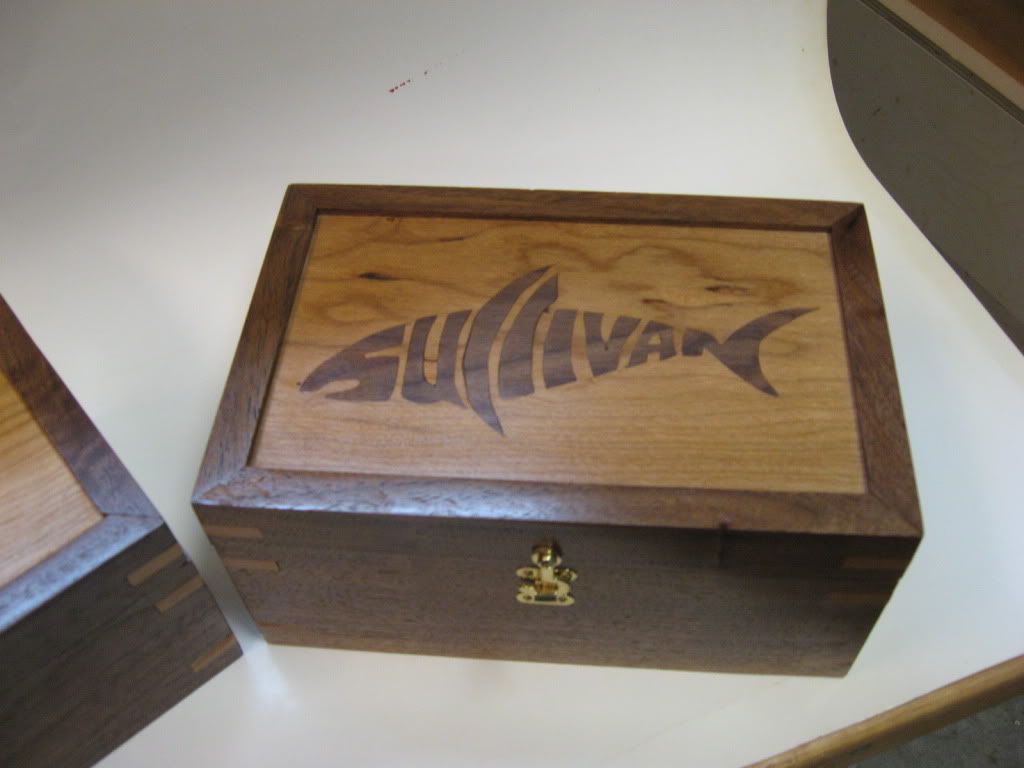

This is a simple example showing how I made the bridges on an inlay but, it works on any type of cutting.

Rog

Print out the words in the font you like and use a pencil, pen or sharpie to mark in bridges to keep letters with centers in place. That works on script also. Once finished the bridges are hardly noticeable on the project.

If you have a bit of drawing talent, you can design your own font. The possibilities are endless!

This is a simple example showing how I made the bridges on an inlay but, it works on any type of cutting.

Rog

NPDH! (no pictures, didn't happen)

NPDH! (no pictures, didn't happen)

I didn't know that Wood magazine was still selling them!

I didn't know that Wood magazine was still selling them!  Very sorry about that folks!

Very sorry about that folks!