OK Jim, I understand completely what your are saying about my "clockwise/counterclockwise" comments. You are right of course, it can get confusing but, I was just trying to illustrate that when you start cutting an item that it must be one continuous cut.

I also realize that it doesn't matter if the inlay is on the top or bottom of the backer but, I find that it is easier to install the (letters in my case) or shape from the front and the correct size to fit into the backer from the top and it can be sanded flush after glue-up. I don't worry about having the angle exactly right or what the back looks like.

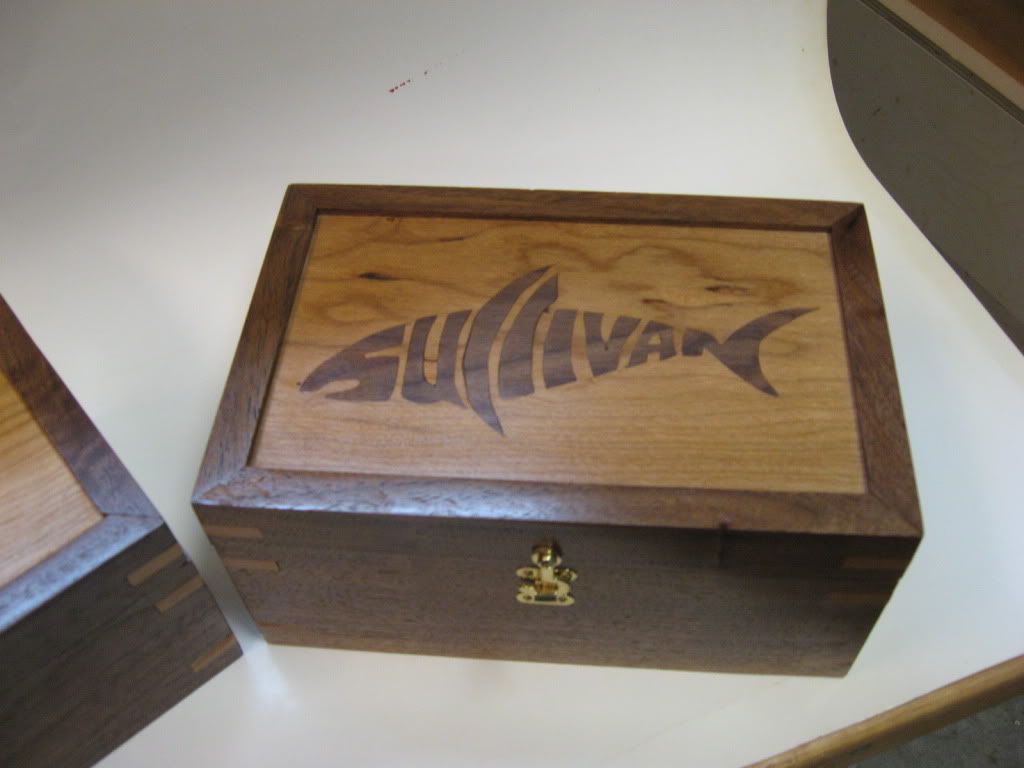

Another example of some inlays that I've done.

This was an earlier piece and you can see the mistakes I made.

Rog